As the saying goes, 'Safety is our No. 1 priority.' This is a compulsory program for SP students to be trained and safety certified before allowing access and work in workshops, Fablabs or studio with fabricating facilities. The objectives are

Here are some equipments and tools introduced to us in the first few lessons. I was amazed at how diverse on the types of equipments used, the school probably spend a ton too.

Contains wrench, screwdrivers, claw Hammer

6 Piece is a kit containing six cordless power tools

HCM-2S

Foam cutting machine

ABM-500S

Plastic bending machine

Here are some digital fabrication equipments and tools introduced to us in the first few lessons. One of the criteria for the final project was to make use of 3D printing, laser cutting and aruduino for our product.

Creates three-dimensional components from CAD models. It mimics the biological process, adding material layer by layer to create a physical part. With 3D printing, you can produce functional shapes, all while using less material than traditional manufacturing methods.

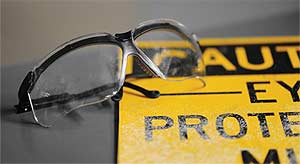

Epilog Fusion M2 Laser Series

Mostly cuts wood and can create parts like puzzles to be fixed together

HCM-2S

For manufacturing of small scale parts

Brother PR-1050X Sewing Machine

An Innovative 10-Needle Home and Small Business Embroidery Machine

Here are all the softwares that I used for this elective, and some reasons to justify my choices.

I'm using Sublime Test 3 as my text editor as my lecturer is using, it is simple and straightforward to use

.png)

I'm using Illustrator as my vector editor as my course requires us to use it

I'm using Photoshop as my graphics editor as my course requires us to use it

I'm using Pickpic as my screen capture and image resizer as it is efficient to take a screenshot and crop it.

I'm using Fusion 360 as my CAD software as it is a Pro CAD software on top of a 3 year Education License provided.

I'm using Chrome as my default browser as it has high speed navigations, and can sync across many devices and Google accounts.

GitHub, Inc. is a provider of Internet hosting for software development and version control using Git. We use it to manage our repositories and version control.

We use Cura to prepare 3D prints, its slicing feature allows us to check how the machine is going to 3d print in layers. It is integrated with CAD software for an easier workflow, and also has custom settings for in-depth control.

LibreCAD is a free computer-aided design application for 2D design. It uses the AutoCAD DXF file format internally for import and save files, and I use it to lay my CAD drawings out and save it in .dxf file before laser cutting them.

The open-source Arduino Software (IDE) makes it easy to write code and upload it to our Arduino Uno board. This software also can be used with any Arduino board.